1. Device Introduction

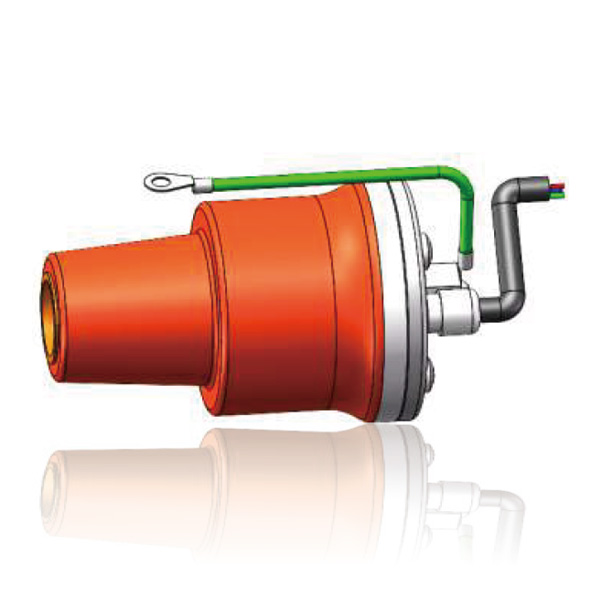

A release is an electro-mechanical device used to disengage the main contacts of a circuit breaker and is a crucial component of the breaker. Vacuum circuit breakers achieve rapid closing and opening, enabling the application of fast transfer technology. This effectively compensates for the shortcomings of traditional automatic transfer equipment and is rapidly being adopted in power supply systems, providing technical assurance for stable power supply to devices.

1.1. Application Scope

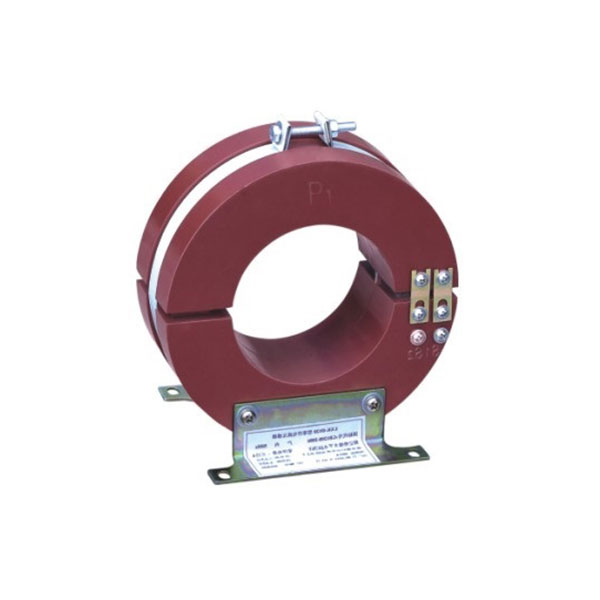

This product is suitable for various voltage level spring operating mechanisms. It requires no alteration to the original mechanism structure; simply replacing the release enables fast tripping. Installation is straightforward. It effectively enhances the safety and reliability of the circuit breaker. It facilitates fault diagnosis, fault zone isolation, and rapid power restoration to non-fault zones, thereby shortening fault repair times and ensuring reliable operation of distribution network lines.

1.2. Product Features

➢ Suitable for various voltage level spring operating mechanisms without changing the original mechanism structure.

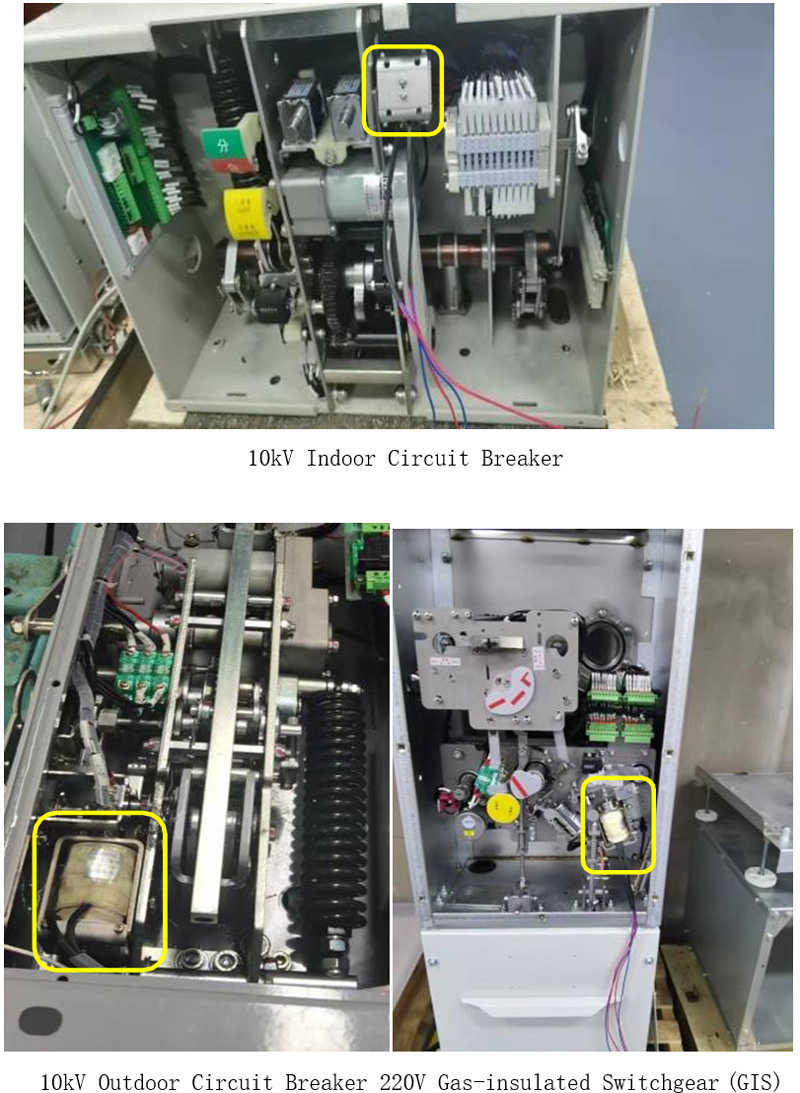

➢ Enables the mechanism's overall opening time to be less than 20ms (at rated voltage and low voltage).

➢ Opening time dispersion is within ±2ms.

1.3. Product Composition

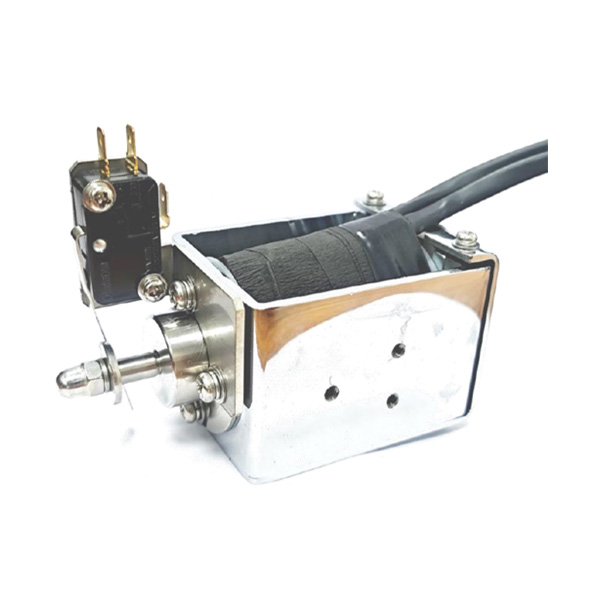

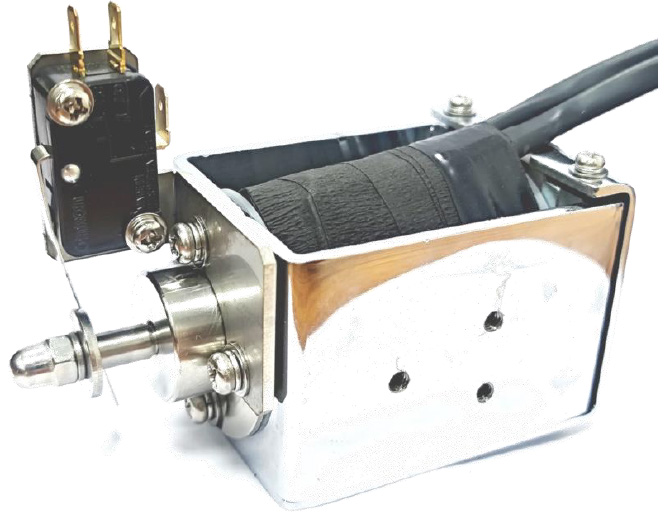

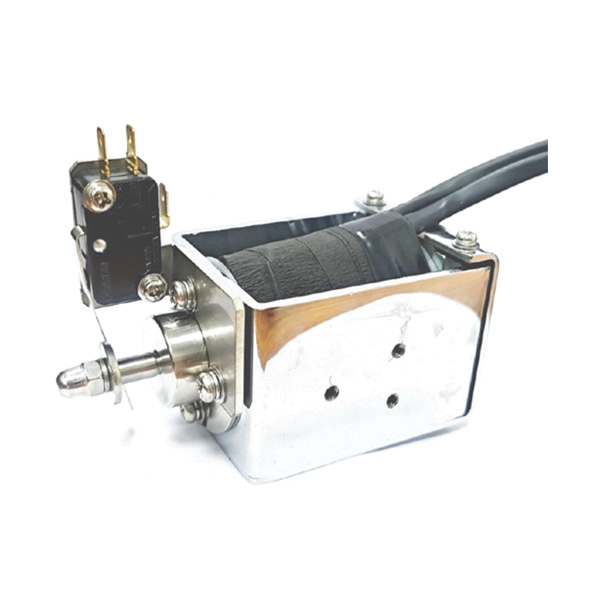

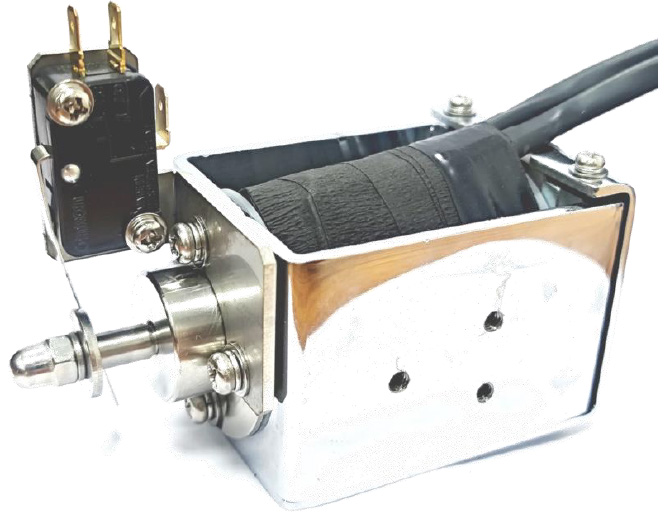

This product mainly consists of three parts: the permanent magnet release, the micro switch, and the control circuit board. These three parts work in coordination to complete the fast tripping action of the circuit breaker.

Release + Micro Switch

Control Circuit Board

2.Technical Parameters

| Model | Rated Voltage(V) | Stroke(mm) | Release Current(A) | Reset Current(A) | Opening Time(ms) |

| SCC530-24 | DC24 | 11 | 12 | 16 | 20 |

| SCC530-48 | DC48 | 11 | 9 | 8 | 20 |

| SCC530-110 | DC110 | 11 | 3.5 | 4 | 20 |

| SCC530-220 | DC220 | 11 | 1.5 | 2 | 20 |

3. Type Test Verification

Verified by type tests, the opening time of this product, both before and after mechanical endurance testing, is within 20ms under conditions of high (110% of rated voltage) and low (65% of rated voltage) voltage.

| SETC MIQC | Mechanical Characteristic Test (Circuit Breaker) | No.20220213A |

| Page 32 | Total 140

Pages |

| Test Items and Results |

| No. | Test Item | Uni t | Techn ical Requi reme

nt | Pre-Mechanical Endurance | Post-Mechanical Endurance |

| A | B | C | A | B | C |

| 1 | Rate d Supp ly Volt age | Contact gap | mm | 9±1 | 8.8~9.3 | 8.7~9.4 | 8.5~8.9 | 8.7~9.2 | 9.3~9.6 | 8.8~9.2 |

| 2 | Over-travel | mm | 3±1 | 2.7~3.2 | 2.6~3.3 | 3.1~3.5 | 2.8~3.3 | 2.4~2.7 | 2.8~3.2 |

| 3 | Avg. closing

speed | m/s | 0.75±

0.2 | 0.79~0.80 | 0.78~0.79 |

| 4 | Avg. opening

speed | m/s | 1.25±

0.3 | 1.16~1.17 | 1.16~1.18 |

| 5 | Closing time | ms | 30~60 | 40.0~40.4 | 40.4~40.6 |

| 6 | Opening

time | ms | 14~20 | 15.0~15.8 | 15.4~15.9 |

| 7 | Closing

asynchronis m | ms | ≤2 | 0.4~0.5 | 0.4~0.5 |

| 8 | Opening

asynchronis | ms | ≤2 | 0.5~0.7 | 0.6~0.7 |

| 9 | | m | | | | |

Contact

bounce | ms | ≤2 | 0.7~0.8 | 0.0~0.0 | 0.0~2.0 | 0.7~0.8 | 0.0~0.0 | 0.0~2.0 |

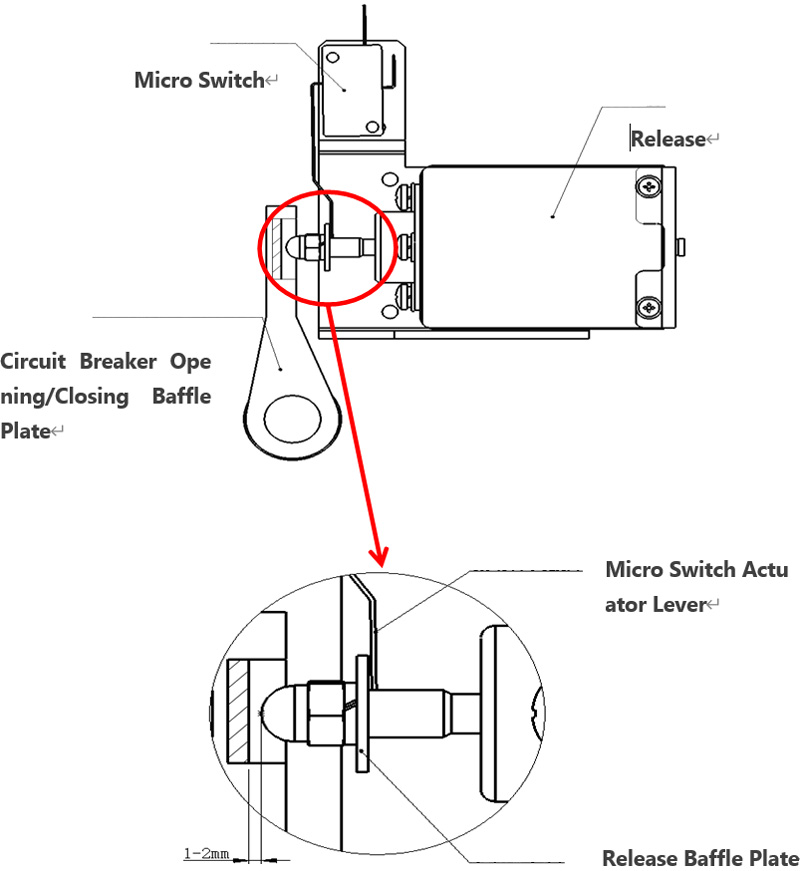

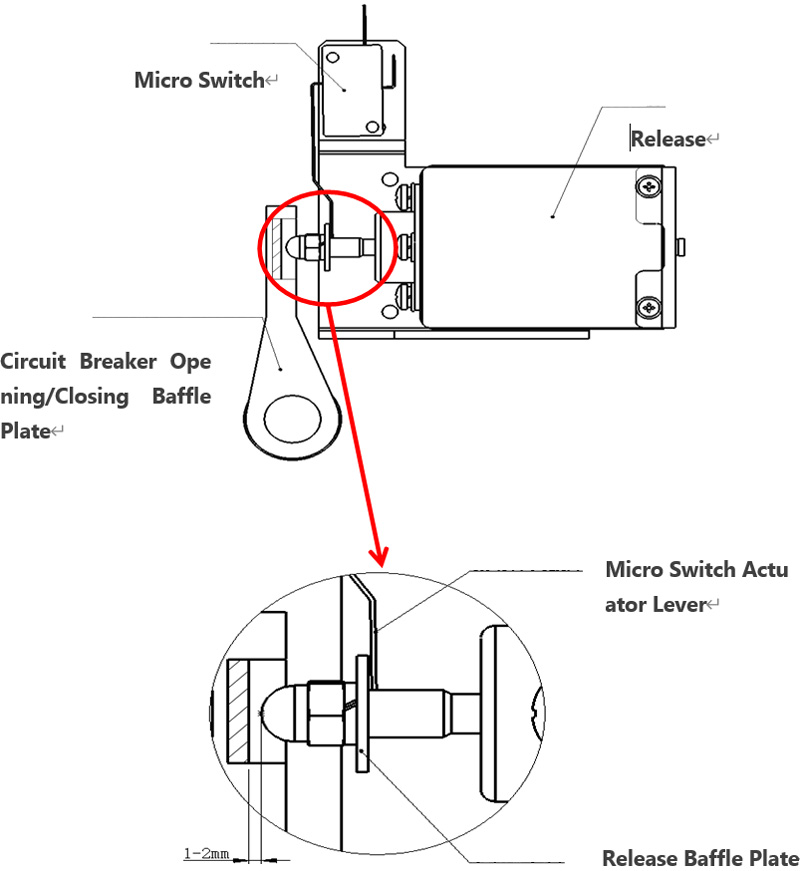

4. Installation Method Example

As shown in the figure above, during installation, the front end of the release should be positioned 1~2mm away from the opening/closi ng plate, and the release must be kept level. Screws secure the relea se to the circuit breaker through the mounting holes. Select the Norm ally Closed (NC) terminal of the micro switch. The micro switch actua tor lever must be placed inside the release's baffle plate. Finally, connect the release circuit into the circuit breaker circuit together with the control circuit board.

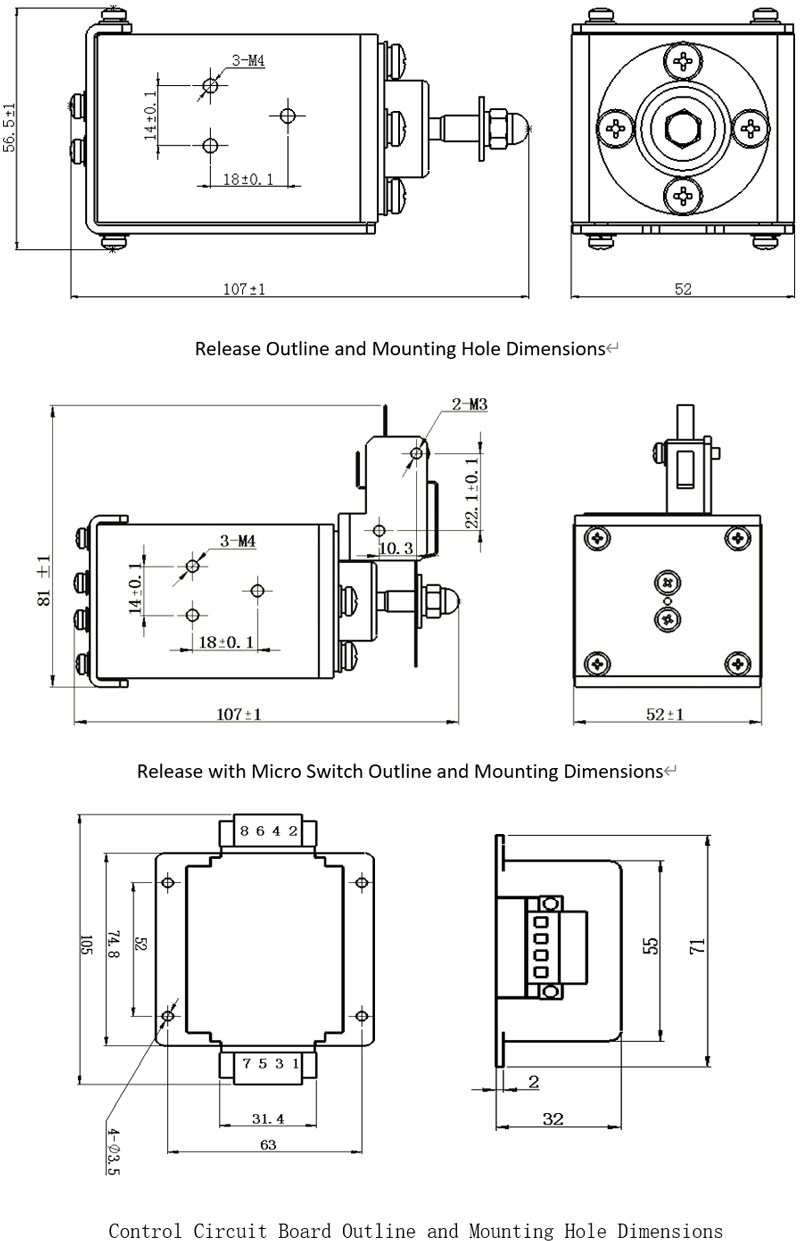

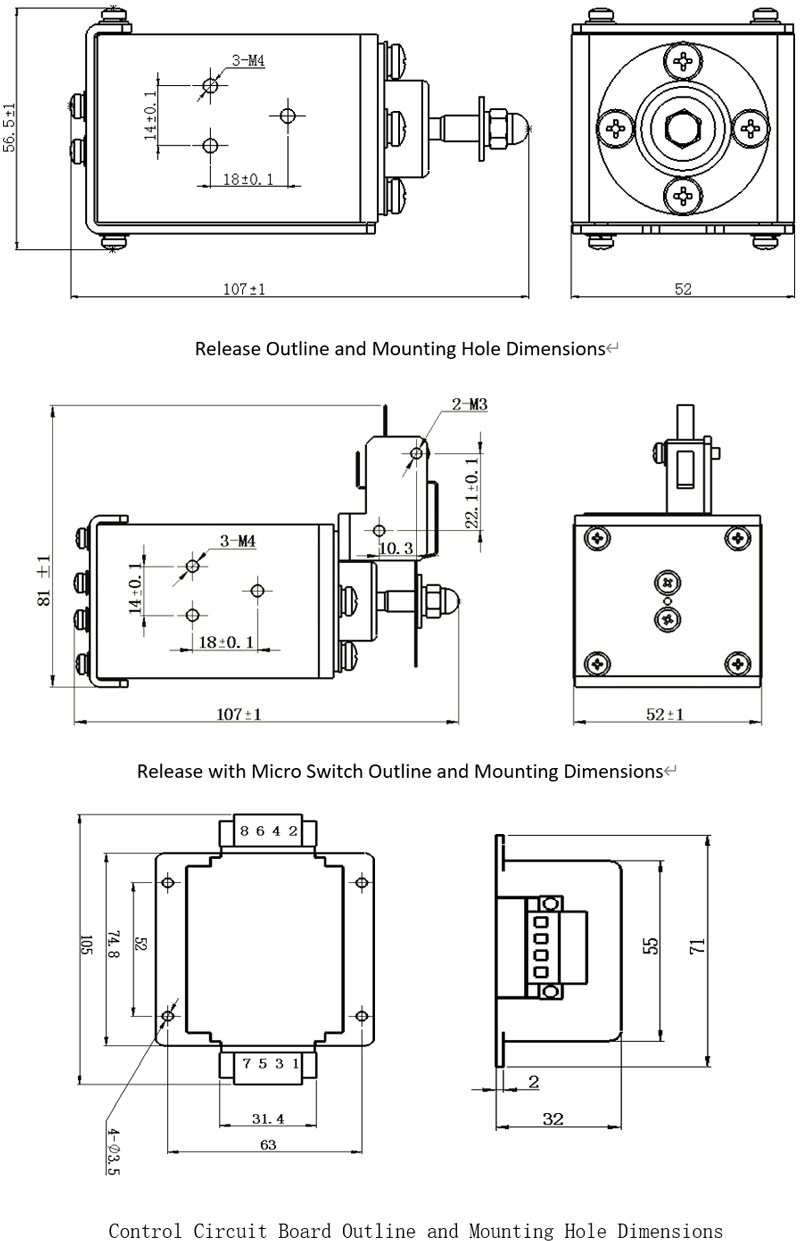

5. Outline and Mounting Hole Dimensions

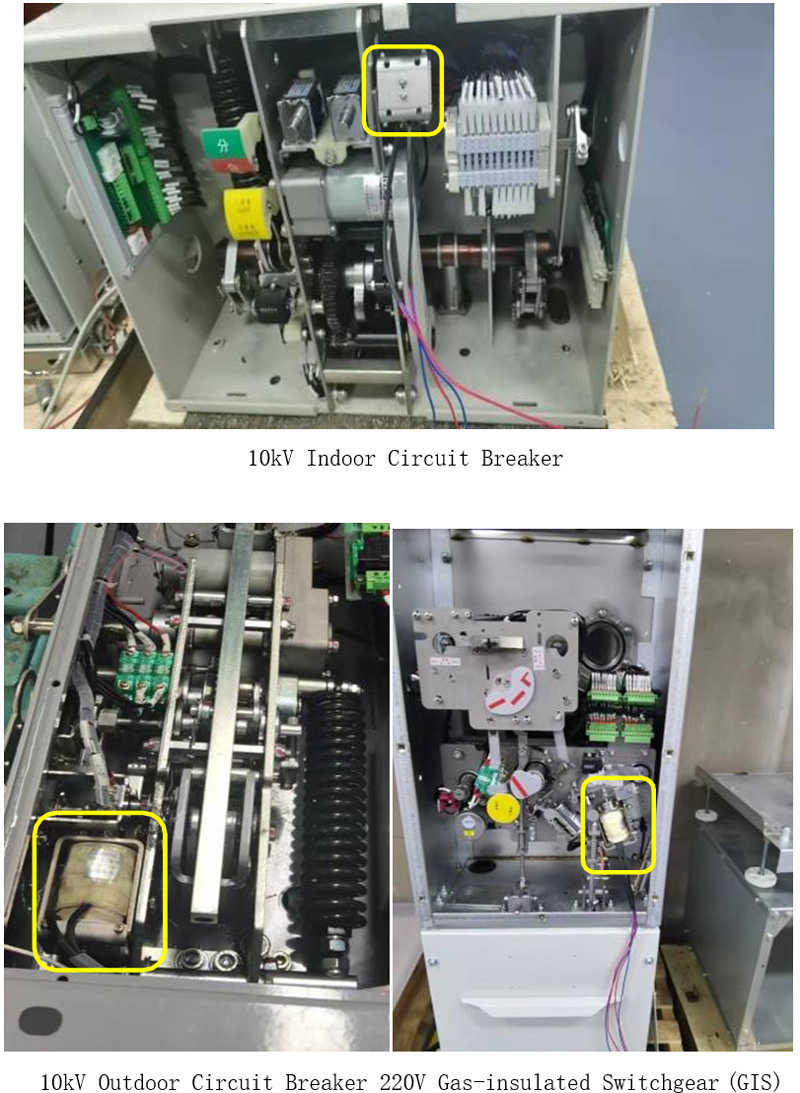

6. Application Examples

No need to change the original structure; simply replacing the release enables fast tripping. Installation is simple.